萊分享 | 兩類景觀亮化電源對比,看完后……

http://www.progcable.com2021年09月10日 13:06教育裝備網

購買景觀亮化電源最關注什么?

哪些使用因素會影響景觀亮化電源壽命及可靠性?

景觀亮化電源結構都有哪幾類設計?

它們之間如何比較?

……

想知道以上問題?那就一起看下去吧!

What do we care about most when buying LED drivers used for landscape lighting?

What factors will affect the lifetime and reliability of LED drivers used for landscape lighting?

What kind of design does the structure of LED drivers used for landscape lighting?

How do we make the right choice?

Read on to get the answers!

購買防雨電源最關注什么?

The problem that customers care about most

在前期產品立項中,萊福德針對購買景觀亮化電源客戶最關心的問題進行了調研,發現大家雖表述各有不同但最終都落腳在了可靠性上。回頭想想,也不難理解——景觀亮化電源常用于戶外的各項公共工程,如出現故障,需要現場搭梯子、腳手架、甚至封鎖路才能維修,不僅維護成本非常高昂,且將直接嚴重影響企業的名聲。

Rain-proof LED driver is often used for landscape lighting. In the new product preparation stage, a survey on the problem that customers do care about most when buying LED drivers used for landscape lighting was conducted by Lifud. And it is found out that the lifetime or reliability of the LED driver, which is closely linked with a company’s reputation is the most concerned problem.

哪些使用因素會影響防雨電源壽命及可靠性?

The factors that affect the lifetime and reliability of LED driver used for landscape lighting

①發熱散熱:電子產品的壽命在很大程度上取決于工作溫度,溫度越高壽命就越短,此時電源本身的發熱與散熱就極為重要了。而其中減少發熱為治本,加強散熱為治標,雙管齊下則為優。

Heating and cooling: The lifetime of electronic products largely depends on its operating temperature. That is to say, the higher the temperature, the shorter the lifetime. Thus, it is necessary for us to reduce heat and at the same time strengthen heat dissipation in order to extend the lifetime of LED drivers. ②雨水潮氣:水就不用解釋了,易造成產品短路,電源直接失效;而潮氣同樣,當濕度達到一定程度(90%以上),電源在該環境同樣容易造成短路失效。

Rain and moisture: It is well-known that water may cause drivers short circuit and even to be damaged. Likewise, when the humidity reaches more than 90%, the LED driver is also easy to be damaged due to short circuit. ③灰塵雜物:灰塵雜物的影響,除了由于擁有酸性、腐蝕性的霉菌和附著物會對電子器件表面造成損傷,還跟后面會講到的加強散熱常用的風扇有關-可能被固體雜物卡死造成電源失效。

Dust and debris: The acid and corrosive fungi or attachments carried by dust and debris not only can cause the surface of electronic devices to be broken, but the driver of the fan used for cooling to be damaged due to short circuit.

應對以上影響常見防雨電源有哪幾類設計?

The common types of design on the LED driver used for landscape lighting to cope with the above problems

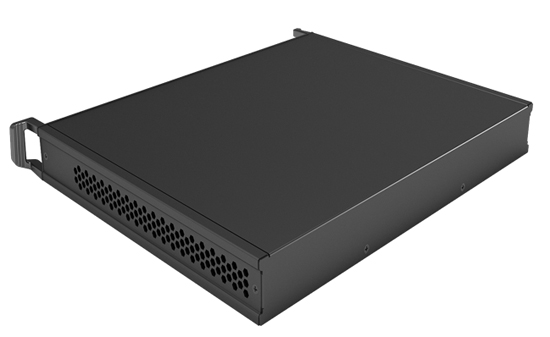

景觀亮化電源結構上主要有兩種設計因素:灌膠、風扇。

There are two main design factors in the structure of the LED driver used for landscape lighting: gluing and Fan.

風扇冷卻

作用:通過強制通風給關鍵發熱器件加強散熱。

副作用:

①風機的使用會降低電源整體效率,提高產品發熱,且增加噪音。

②故障率增高,運輸、跌落、灰塵雜質、潮水……等都對風扇產生損害影響,一旦風扇故障,電源很快就會失效。

Fan cooling

Cooling: The heat dissipation (cooling) of key heating devices is enhanced by forced ventilation.Side effects:①The overall efficiency of the LED driver will be reduced by fan cooling. And also the use of fan will increase heating and noise.② The fan used for cooling is easy to be damaged by transportation, falling, dust and debris, tide and etc, which means the LED driver will be damaged subsequently.

自然冷卻(無風扇)

散熱:通過外殼自然散熱。副作用:由于沒有風機強制散熱,就要求產品本身發熱低、導熱好,對技術及工藝有更高的要求。如電路設計:效率越高,發熱越低。

Natural coolingCooling: It can be achieved naturally through the case of the LED driver.Side effects: The driver is required to have low heat, good heat conduction, better technology and process, such as circuit design: the higher the efficiency, the lower the heat.

半灌膠

作用:

①防止局部溫度過高。對元器件所產生的熱量進行傳導、散發,加強產品導熱散熱。

②提高防潮性能。部分元器件已被導熱膠覆蓋,能夠充分防潮。

③提高穩定性.導熱(絕緣)膠覆蓋了PCB及部分元器件,絕緣性能穩定,且更加穩固、牢靠,能夠充分抵抗沖擊、振動。

副作用:成本提高

Semi-gluingFunction: ①Prevent local temperature from being too high.This type of design is aimed to strengthen the thermal conductivity and heat dissipation of products by conducting and sending out the heat generated by components.②Improve humidity resistance.Part of components have been covered with thermal conductive adhesive, which can achieve humidity resistance.③Improve stability.Thermal conductive (insulation) adhesive covers PCB and part of components, which can fully resist impact and vibration owing to its stable insulation performance.Side effects: Higher cost 根據以上因素,景觀亮化電源結構主要有以下兩種設計:①風扇冷卻常規防雨電源;②自然冷卻半灌膠防雨電源;

2 types of the LED driver used for landscape lighting come into being based on the above factors-natural cooling semi-glue rain-proof LED driver and fan cooling non-gluing LED driver.

設計性能比較

Comparison of these designs

注:以下僅在同一生產水平下對結構設計進行比較,因為同樣的設計,不同廠家由于參數、工藝、元器件等不同,最終產品穩定性也會有較大差異。

Note: The structural design is only compared under the same production level. Because different manufacturers have different parameters, processes and components for the same design. Thus the stability of the final product will be greatly different.

|

項目 |

風扇冷卻 常規防雨電源 |

自然冷卻 半灌膠防雨電源 |

|

溫升 |

中 |

中 |

|

防水 |

低 |

高 |

|

防塵 |

低 |

高 |

|

可靠性 |

低 |

優 |

|

Term |

Fan cooling non-gluing LED driver |

Natural cooling semi-glue rain-proof LED driver |

|

Case Temperature |

Average |

Average |

|

Water-proof |

Low |

High |

|

Dust-proof |

Low |

High |

|

Stability |

Poor |

Excellent |

注:紅色字體為劣勢,綠色字體為優勢。總結:在相同生產工藝水平下自然冷卻半灌膠防雨電源更可靠。但由于沒有風機強制散熱,該結構要求產品本身發熱低、導熱好,對企業技術及生產工藝有更高的要求。如電路設計要求能達到更高的效率(效率越高,發熱越低)。

Note: The red font is the disadvantage, and the green one is the advantage.Conclusion: the natural cooling semi-glue rain-proof LED driver is more reliable under the same production technology level.The driver itself is required to have low heat, good heat conduction and heat dissipation, which can be also regarded as higher requirements on the technology and process of enterprises. Such as circuit design: the higher the efficiency, the lower the heat.

始于設計,嚴于工藝

Start with Design·Strict with Technology

萊福德電源,防雨電源新品介紹,您值得擁有[機智]視頻號

萊福德景觀亮化防雨電源采用自然冷卻半灌膠結構,通過設計和工藝兩個方面嚴格保障產品可靠性。

Natural cooling and semi-gluing structure is applied in Lifud rain-proof LED driver used for landscape lighting., thus the product reliability in terms of design and process can be ensured strictly.

設計上

· 新型電路,使效率高達94.5%,高于市面同類一流產品2-3個百分點;

· 降低發熱,整體殼溫低于同類產品10-20℃,更可靠!

· 高PF(>0.95)低THD(<10%),提高電線傳輸能力,可降低電線成本;

Design:· New circuit is used, making the efficiency up to 94.5%, higher than the market similar first-class products 2-3 percentage points.· Heating can be reduced, making the overall case temperature is 10-20℃ lower than similar products.· Wire costs can be reduced by improving transmission capacity. (high PF>0.95 and low THD<10%)

工藝上

· 雙面板設計,雙面銅箔+焊接孔電鍍銅,焊接面積大,焊接牢固,更可靠!

Process:Double PCB design, double-sided copper foil and electroplated copper for welding holes are applied in our rain-proof LED drivers, making it more solid and reliable.

注:本文為推廣文案,不代表本站觀點。

更多信息請查看企業專區:http://www.progcable.com/cp55214

責任編輯:黃程程

本文鏈接:TOP↑

首頁

首頁